Investing in the HX12000PB37S is an investment in future-proofing your production floor.

|

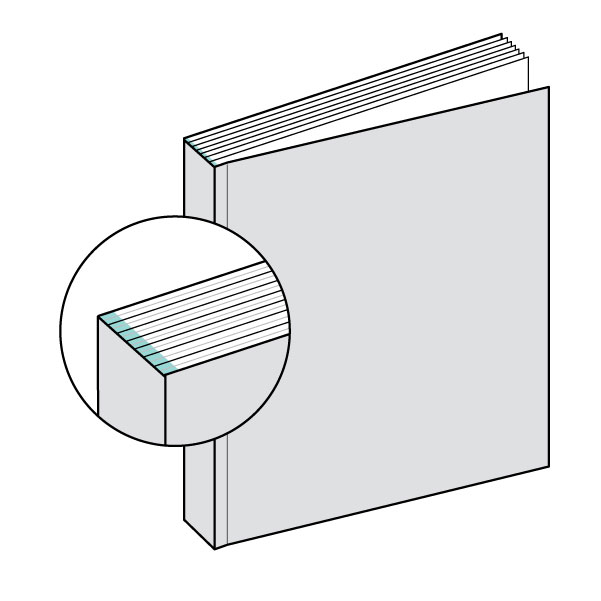

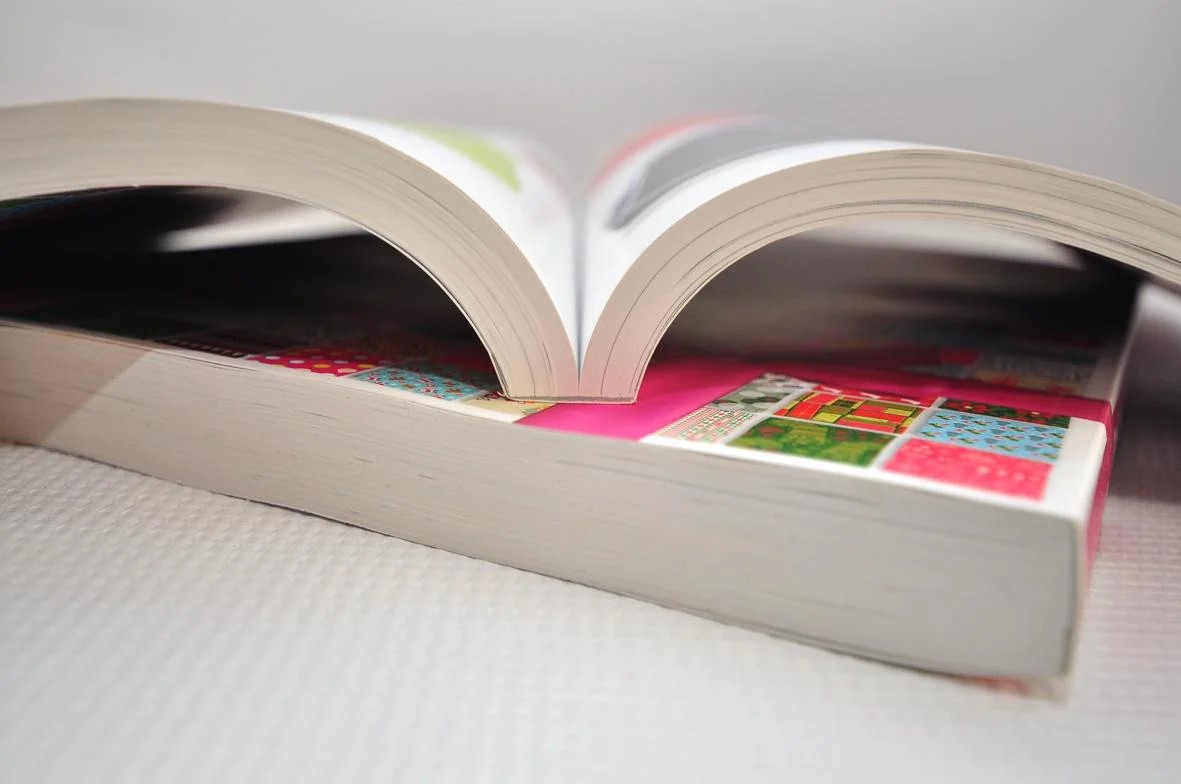

The modern bindery is undergoing a technological renaissance, shifting away from heavy mechanical gears and shafts toward the precision of digital control and servo automation. Leading this charge is the HX12000PB37S, a high-speed perfect binding line that leverages a fully servo-driven automatic control system to deliver unparalleled precision. In traditional binding, changing job parameters often required manual wrench work and complex mechanical timing adjustments. The HX12000PB37S changes this paradigm by utilizing independent servo motors to drive critical components. This not only simplifies operation but also significantly reduces mechanical wear and maintenance, as fewer drive chains and gears are required to synchronize the machine's complex movements. A standout feature of the HX12000PB37S is its intelligent automation in the gluing and spine preparation sections. The machine is equipped with automatic glue adjustment capabilities, a critical feature when switching between different book thicknesses or paper types. Whether applying spine glue, side glue, or secondary spine glue, the system ensures consistent application thickness regardless of the machine's running speed. This is vital because variations in speed can often lead to uneven glue film in purely mechanical systems. The servo control ensures that the glue rollers match the book block's velocity perfectly, eliminating issues like glue build-up or skipping, which are common causes of bindery waste.  The integration of the HX12000PB37S aligns perfectly with the principles of Industry 4.0 and the "Smart Print Factory". The line integrates the gathering system, weighing inspection, reject stations, and the high-speed three-knife trimmer into a cohesive, communicative ecosystem. Data flows between these modules to ensure synchronization. For instance, if the gathering machine detects a misfeed, the system knows exactly which clamp holds the defective block and rejects it automatically at the emergency reject station after the binder output. This level of intelligent error handling reduces the need for constant operator intervention, allowing staff to focus on logistics and quality assurance rather than unjamming machines.  The weighing inspection system is another technological highlight that ensures the integrity of every shipped product. Positioned strategically after the binding process, this system verifies that every book contains the correct number of signatures and inserts. In high-speed environments producing 13,000 books per hour, manual inspection is impossible. The automated weighing unit acts as a relentless quality gatekeeper, ensuring that incomplete books never reach the stacking conveyor. This technology is essential for maintaining client trust, particularly in sectors like educational publishing where a missing page constitutes a critical product failure.  Investing in the HX12000PB37S is an investment in future-proofing your production floor. The machine's capability to handle book thicknesses from 3mm to 40mm and cover dimensions up to 675mm x 400mm demonstrates its flexibility alongside its automation. As print runs become more segmented and turnaround times shrink, the ability to rely on servo-controlled precision for quick changeovers and consistent quality becomes a massive competitive advantage. The HX12000PB37S offers the technological sophistication required to thrive in the modern, data-driven printing industry. |

| Tag:smart bindery equipment,book binding,book binding machine,perfect binding book,perfect binding |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!