|

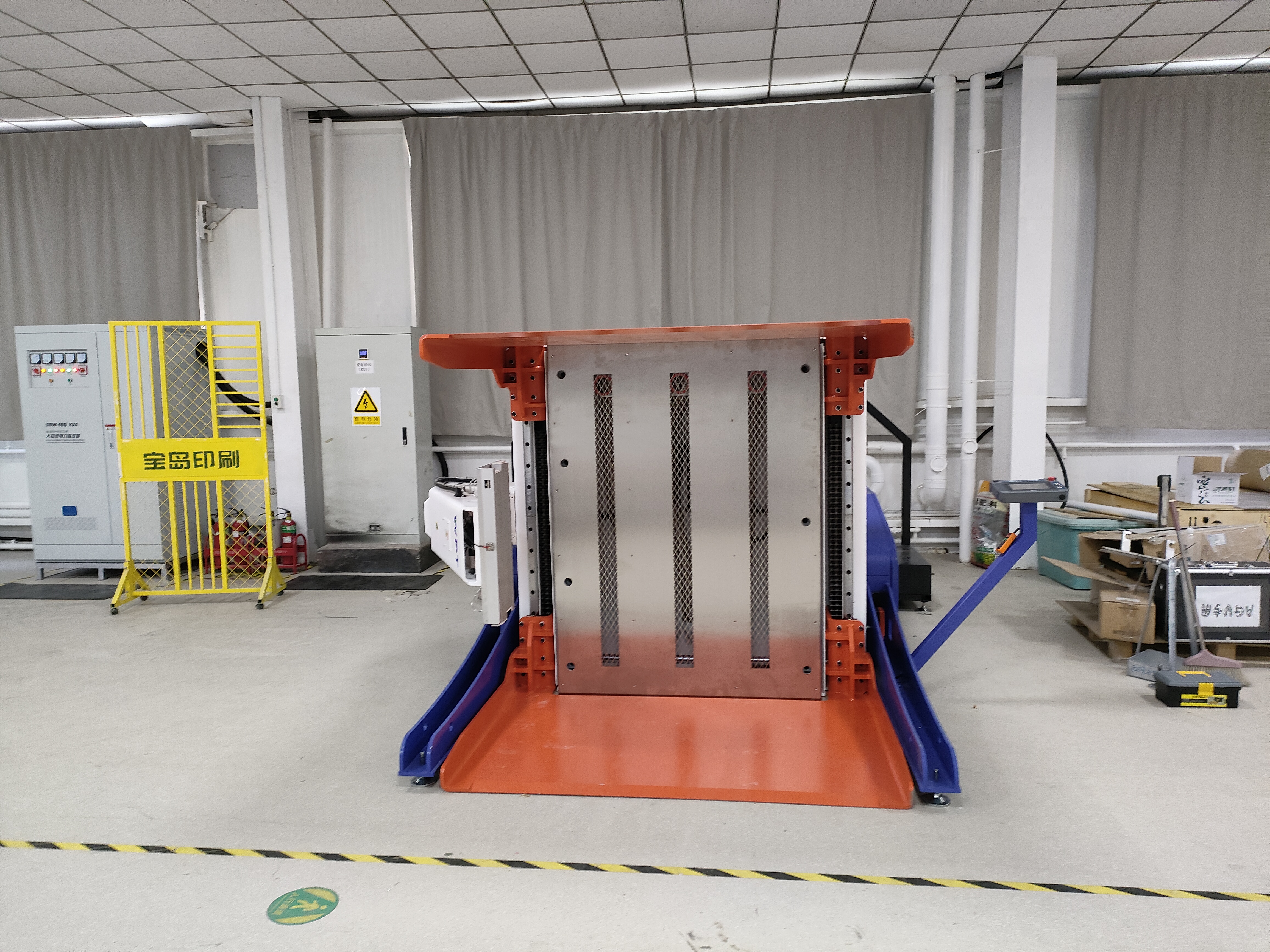

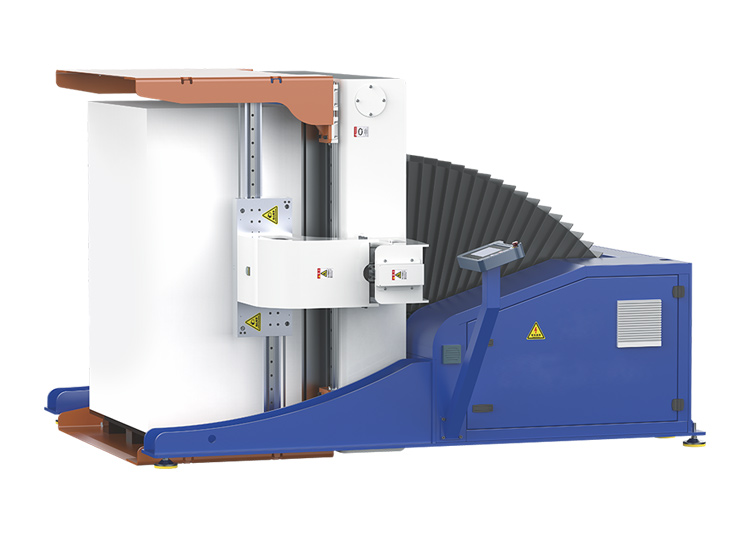

Integrating automation should simplify processes, not complicate them. The Paper Pile Turner excels by offering a streamlined workflow that dramatically speeds up pallet handling while requiring minimal operator intervention. Let's break down its efficient operation:

Automatic Paper Pile Turner

A Step-by-Step Efficiency Engine:  Loading: A hydraulic trolley effortlessly pushes the loaded paper pallet directly into the turner machine.  Securing & Turning: Automated clamping mechanisms securely grip the pile. The hydraulic system then lifts the entire stack to a horizontal position and rotates it precisely 180 degrees.  Cleaning & Alignment: Once turned (or sometimes before/after depending on the need), the machine activates its high-pressure air jets and vibration platform. This powerful combination simultaneously: Removes Dust & Debris: Blasting away paper fibers, scraps, and printing powder. Loosens Sheets: Separating individual sheets to prevent adhesion and double feeds. Aligns the Stack: Vibrating the pile against stops ensures perfectly squared edges on all sides.

Completion & Unloading: After the cleaning and aligning cycle, the machine smoothly rotates the pile back to the upright position (if needed) and releases the clamps. The hydraulic trolley then retrieves the processed pallet, ready for the next stage.

Speed That Transforms Production:

This entire sequence – turning, dusting, loosening, and aligning – is remarkably fast. On average, a well-operated pile turner completes the process for a full pallet in approximately 3 minutes. This speed is a game-changer compared to manual methods, which are slow, physically demanding, and prone to errors. Designed for Simplicity: Intuitive Control: Operators manage the process via user-friendly panels, allowing control over air volume, vibration intensity, clamping pressure, and cycle initiation. Clear displays make monitoring straightforward. Minimal Training: The automation and intuitive controls mean extensive operator training is unnecessary. Staff can become proficient quickly. Reduced Labor Intensity: The machine eliminates the most strenuous and repetitive manual tasks associated with pile handling and preparation.

By condensing multiple critical pre-press and post-press tasks into a single, rapid, automated cycle, the paper pile turner becomes a pivotal hub for workflow optimization. It significantly reduces pallet handling time, minimizes manual labor, and ensures piles are perfectly prepared for the next stage, whether printing, finishing, or packaging. |